|

Jinan Zhongke New Material Co., LTD.

|

SiC ceramic foam filter special size

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

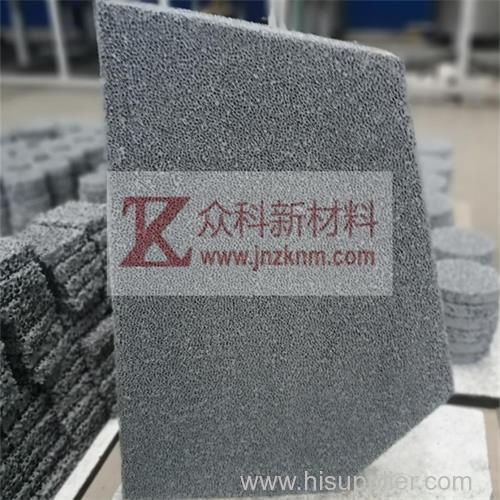

SiC Ceramic Foam Filter is used for casting steel, casting iron and nonferrous metal filtration and purification in foundry industry.

1,ZK series foam ceramic filter is made of fine ceramics materials after a special process, which can be used for casting steel, casting iron and nonferrous metal filtration and purification, it can greatly reduce sand holes, slag inclusion, porosity inclusions and other defects, and improve the surface quality, better the machining performance, increase the mechanical properties. It is the ideal for producing high quality castings. ZK series foam ceramic filter with high void ratio, strength, good thermal shock resistance, and has the advantages for bearing large flow of hot metal filter.

2,Common Sizes:

1)Round: D40, D50, D60, D70, D80, ^ D400

Square / rectangular: 40x40, 50x50, 55x55, 75x50, 75x75,^ 400x400

Other size, special shape are available on request.

2)Thickness: 12mm, 15mm, 20mm, 22 mm, 25mm, 30mm, 40mm

Other size, special thickness are available on request.

3)Standard: PPI 10, 15, 20, 30.....40

Depending on the dimensions, the filters may be available in PPI 15,20, 30 and 40.

3,Various sizes filter the reference weight of the liquid metal (10PPI):

Conditions of use size | Ductile Iron(kg) | Grey Iron(kg) | The biggest runner cross-sectional area (m2) |

30/33/22 | 25 | 50 | 350 |

30/50/22 | 30 | 60 | 420 |

50/50/22 | 50 | 100 | 700 |

75/50/22 | 75 | 150 | 1050 |

100/50/22 | 100 | 200 | 1400 |

75/75/22 | 110 | 220 | 1570 |

4, Attention:

Pay attention to care when loading and unloading, handling, protect the goods against press.

Packing: carton packing , or according to the requirements of customers.

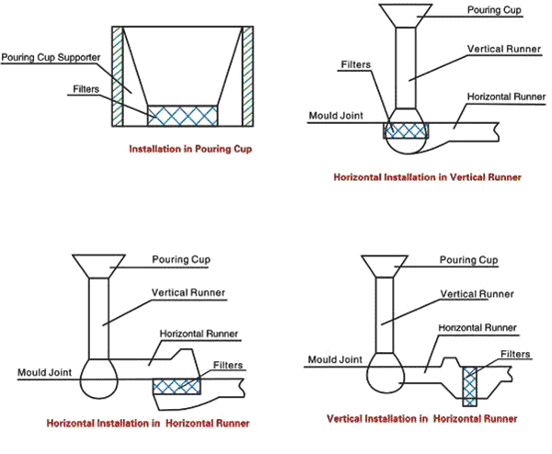

5,The Foam Ceramic Filter Typical Placed Way:

ZK series foam ceramic filter can be placed in any part of the gating system, but should be choosed according to the casting characteristics and specific production conditions. Generally speaking, the more close to the gate, the better for filtering purification effect. Here are several typical ways of placement:

1. Installation in Pouring cup: usually used in precision casting and iron mould coated sand casting.

2. Horizontal Installation in Vertical Runner: usually used in the whole case pouring molten iron is not much, especially suitable for Vertical Runner is located in the center of mould and branch runner gating system.

3. Horizontal Installation in Horizontal Runner: liquid metal filling smoothly, to avoid the direct impact of metal liquid to filter. Better to play the slag function of the upper model runner, and was convenient.

4. Vertical Installation in Horizontal Runner: metal fluid flow faster, have a good filling ability: when molten metal impact the surface of filter, the impact resistant ability should be considered.