|

Jinan Zhongke New Material Co., LTD.

|

Ceramic foam filter for the filtration of molten Iron copper aluminum and alloy

| Payment Terms: | T/T,L/C |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

SiC Ceramic Foam Filter is used for casting steel, casting iron and nonferrous metal filtration and purification in foundry industry.

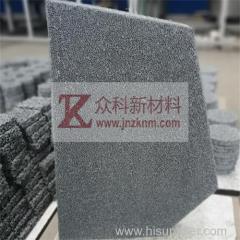

Ceramic silicon carbide foam filters

Application:For the filtration of molten Iron,copper,aluminum,and alloy.

Silicon carbide ceramic foam filters are designed to improve the quality of nodular, grey and malleable iron castings. The filter can effectively remove non-metallic inclusions including slag and dross from the molten metal stream. Additionally, they aid in reducing turbulence in the gating system. SIC ceramic foam filter's outstanding thermal shock resistance and high strength properties were developed for superior performance in extreme iron foundry applications.

• Sand casting

• Investment casting

• Shell casting

• Low-pressure die casting

• Permanent mould casting

Advantages:

• Simplified and shorten gating system,increasing yield.

• Remove tiny slag effectively and purify molten metal.

• Well-distributed molten metal and improve performance.

• Quiet laminar flow of molten metal.

Filtration effect of Ceramic FoamFilter:

• Increase yield rate by 5-10%

• Reduce reject rate by 15-30%

• Improve Compressive strength and rigidity by 5-10%

• Improve bending resistance strength by 5-8%

• Improve the machining performance of casting

• Filtration: reduce the impurities which could lead to the casting defects (inclusions)

• Elimination of bubbles in metal

• Regulate and homogenize the metal flow, reduce the oxidation, improve casting quality

Product Features:

• Precise size.The control of size is processed from filter media sponge cutting to final sinter.

• High strength and free from loose debris.Special formula and technique adjustment together with good

package is to make sure it prevent from debris either during transportation or molten metal pouring.

• Branded main material. Branded filter media sponge with strictly inspection to make sure uniform hole

with high porosity.Triple check on pores of sponge:before cutting,cutted,sintered.

• High purity of raw materials,high refractory and good thermal shock resistance.

Physical Property:

• Main material Silicon Carbide

• Aplied Temp.(℃) ≤1500

• Color Gray-black

• Hole density (PPI) (PPI=pore per linear inch) 10/20/30

• Porosity(%) 80-90

• Compressive Strength(MPa) ≥1.0

• Bulk Density(g/cm3) 0.36-0.5

• Thermal shock resistance 6times/1100℃ to room temp.

• High temperature Bending strength (1200℃)MPa ≥0.6

Size and porosities:

• Different size can be made upon customer request.

• Length*width*height=(35-200)*(35-200)*(10-30)mm

• With round,square and rectangle shape.

• Tolerance:±(1-2)mm

• Pore size: 10PPI/20PPI/30PPI

• Tolerance:± 1-2PPI

Principle Of Using Filter:

• Set the filters as close as possible of the casting.

• Use simple gating system without dirt trap ( improve yield).

• The working area of filter should be 4–6 times of the section of chocked flow in gating system to make

sure that the pouring speed is not affected.

• Select the proper filters according to types of metal and pouring temperature.

• The higher porosity, the better filtration.